Solutions

Warehouse

Management System

Monitor, manage and optimise

all your warehouse operations

A realistic digital image of your logistics

- Cloud

-

Shed your worries regarding infrastructure and operations. Just log in and use the system. Quickly, easily, and without a care.

- A digital image of your warehouses

-

You’ll have every event in your warehouse and workshop on file. So you’ll have the latest information on your materials – their quantities, locations, and movements. See them from receipt, to put-away and dispensing into production, all the way to shipping.

- Optimising stocks and increasing warehouse productivity

-

Manage people and equipment without losses by ensuring all your warehouse handling is free of errors, long searches and unneeded actions and downtimes.

- Full automation

-

Control all your automation equipment and its surrounding manual processes from one place.

- Traceability

-

Get unambiguous forward and backward traceability with precision down to the individual unit, box, carrier and batch.

Our customers

Benefits of deploying a WMS with us

A clear view of every worker and their performance

A view of individual output levels, checking of rules compliance and identification of misconfigured processes.

Controlling advanced logistics equipment

Communication with both simple technologies and advanced equipment such as VNA, ASRS, AutoStore, AGVs and AMR using an intelligent interface.

Optimisation and visualisation

Proposals for changes to how materials are stored based on ABC and XYZ analyses. Recommendations of the optimum path through the warehouse for warehouse workers.

Task management and escalations

Allocation of tasks among people and machines; work queue management. Notifications and escalations for non-standard situations.

Kanban, replenishment and Just in Time

Management of processes for continuous replenishment of production, from the supplier out to the production line.

Yard Management

Online communication with shippers, ordering of shipments, planning and management for loading and unloading.

Multi-client

One logistics system for multiple companies with different supplier concepts based on automotive standards.

Configurability

Configuration of processes to precisely fit your current needs. This solution is based on 1,600 predefined process templates.

“A WMS is an essential foundation. You’ll be more effective when you integrate logistics with manufacturing, quality and automation. Synchronise processes, people and technologies and interconnect the materials flow from receipt out to shipping.“

Vít Glasl Sales Manager

Base Your Decisions on Data

Capture reality in a virtual environment

Real-time reporting provides an instant overview of your production and logistics processes in one place. Monitor performance down to the level of individual work centres. Get support for efficiently managing processes in your hall and motivating your workers. Use data visualisation in a digital twin to gain a quick understanding of the current situation and support for your decisions.

Optimize your processes by analysing and mining your data

Thanks to the analysis of historical data, you can uncover key patterns and bottlenecks in manufacturing and logistics. Expanding this retrospective with a prediction of your results for the next week or month will ease your decision-making. In addition, interconnecting analytical tools with other systems supports the automatic optimisation of warehouse operations and increases overall operational efficiency.

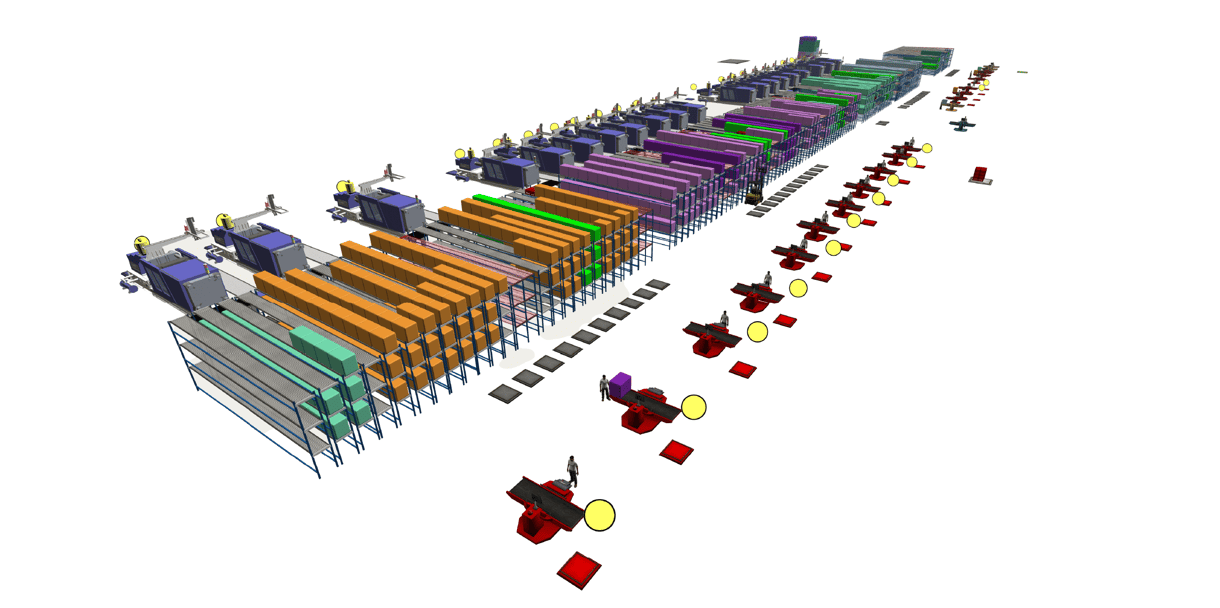

Model solution variants and gain a firm grasp of complex systems

Can't decide on a solution variant? Want to know the performance of a new design, or its critical points? Dynamic simulation in the FlexSim tool will answer your questions even before the project begins. You can verify and fine-tune every change during subsequent optimisation. FlexSim learns with the help of AI (reinforcement learning), enabling it to solve complex tasks almost in real time.

Interconnect logistics processes with other systems

SAP SOLUTION

WMS within SAP system

A solution that makes use of your existing SAP system and its infrastructure and data.

OTHER SOLUTIONS

WMS system as a separate solution

Gain the benefits of a WMS solution inside Aimtec DCIx.

Supplement your WMS solution with Zebra devices

Zebra Technologies offers a broad portfolio of products and services for automatic identification. We’ll help you to choose the best technologies.

Case study

A warehouse logic transformation increased capacity and handling enormously

Storage positions and handling were increased, and warehouse throughput went up 40%. Read our case study on successful warehouse automation.

Aimtec Insights

Get in touch

Want to learn more about this solution? Contact an Aimtec specialist. They’ll show you all its specifics, along with examples of specific deployments.

Daniel Choc Senior Business Consultant