Products

Aimtec Data Intelligence

Benefit from all the data at your disposal. At top quality

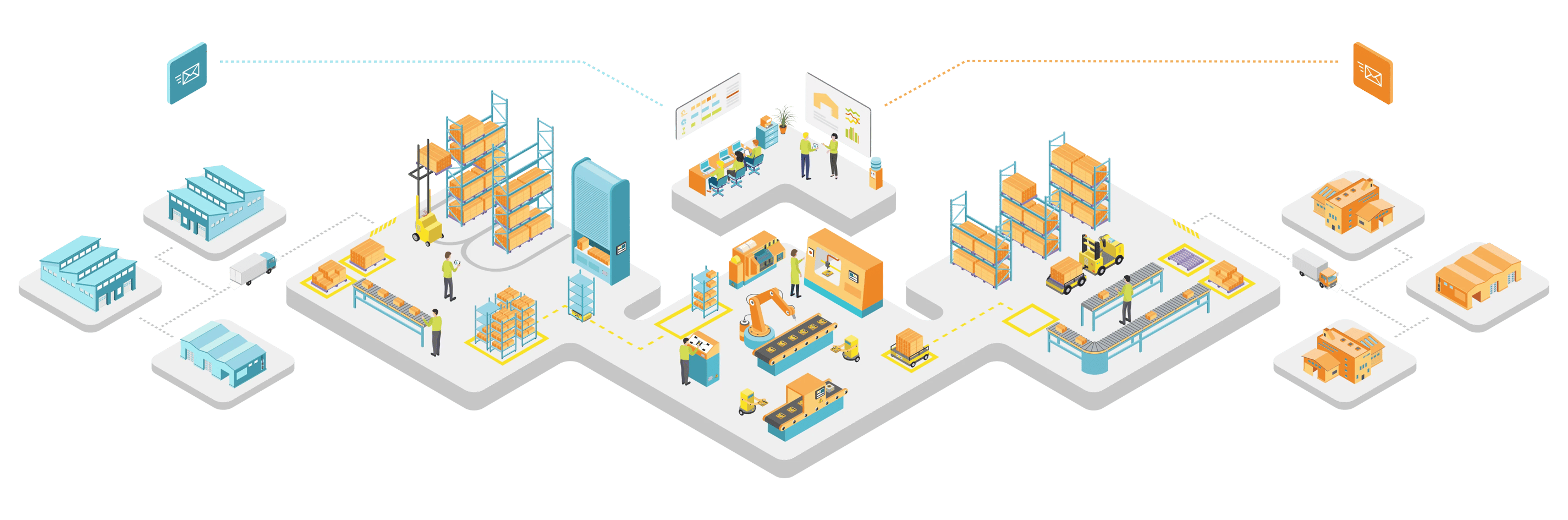

Digitalisation and system automation go hand in hand with the generation and subsequent processing of ever-larger amounts of data. For your data management processes, use a tool that’s tailor-made for manufacturers, based on practical experience acquired during dozens of digitalisation projects.

- 8+

YEARS OF EXPERIENCE

- 7/2

- support

- 75+

- data checks

Where will this system help you?

MOM

Manufacturing

Reporting

Why Aimtec Data Intelligence?

A system that’s tailor-made for manufacturers

You’ll benefit from our 27 years of experience in digital transformation of manufacturing companies.

A unified data structure

Gain a foundation for good managerial decision-making thanks to standardised data organised into a unified structure.

Rapid deployment

Because it’s flexible and lean, you can start using this solution in just weeks after analysing and defining your needs.

Frequently asked questions

- How does the system work with master data?

-

This solution runs a series of ongoing checks of master data, from a simple search for extreme or threshold values, to cross-checking, all the way to comprehensive verification of outputs based on our experience with manufacturing standards. The output is a notification of any missing or erroneous values, which you can then easily correct.

- What can I do to keep my interconnected systems working correctly?

-

The quality of a system’s output is directly proportionate to the quality of its input data. With our solution, you’ll be preparing the data destined for further processing and eliminating deviations that would otherwise introduce errors into your work.

- How often do I need to check the quality of my data?

-

To ensure that your master data is always rising in quality, we recommend checking it continuously. With our solution, you’ll be providing continual monitoring and a foundation for systematic data cleansing.

“We know that data quality is a topic that troubles practically everyone who takes digitalisation seriously. That’s why we’ve tapped into our experience to design a lean solution for supporting management of this area. You can deploy it quickly – thus taking your first step towards precise and unified data.”

Vlastimil Juračka APS Development Manager

Interested?

Want to learn more about Aimtec Data Intelligence? Eager to see some example deployments? Contact our specialists.

Other special features of the system

- System respecting best practices

-

Its data quality checks are preconfigured based on our customers’ most frequent requests.

- A cloud platform

-

Aimtec Data Intelligence operates as a layer between systems and their surroundings – both at the level of internal systems and on neighbouring portals and web services.

- Diverse data governance tools

-

This system offers both basic and advanced processes for data management, cleansing and integration.

- Business functionality

-

It plans, analyses and performs advanced calculations on the data from your ERP, such as corrections to the MRP calculation.

- The data cleansing process

-

Aimtec Data Intelligence guides the user through the continuous process of data cleansing and rectification, based on a unique cleansing process and reports that show any errors found in manufacturing data.

- Aimtec Data Intelligence Solver

-

It optimizes the solution of complex tasks with the support of artificial intelligence (AI) to achieve accurate results in a short time.

Case study

Digitalising the planning of one of the toughest manufacturing processes

Magna manufactures plastic components for passenger automobiles. This company has some of the toughest and most complex manufacturing processes in the industry. And Asprova APS provides efficient planning at Magna.

Aimtec Insights

Get in touch

Want to learn more about Aimtec Data Intelligence? Contact an Aimtec specialist. They’ll show you further specifications, including examples of specific deployments.

Václav Kalina Business Consultant Production Planning Solutions