Transparent and efficient SAP processes: Aimtec optimizes warehouse management at ZELTWANGER company

- 27/2/2025

The digitalisation specialist Aimtec is ensuring efficiency and transparency for warehouse management processes at ZELTWANGER’s plant in Tübingen, Germany. Thanks to the deployment of Aimtec SCIx, an extension solution within SAP, this medium-sized company was able to achieve maximum transparency for its warehouse stocks and digitalise work processes to the fullest. This has improved the utilisation of warehouse capacities and minimised the error rate. The result is more efficient production throughput and time savings of up to 60%.

A lack of transparency in warehouse management led to low efficiency

ZELTWANGER uses SAP to map and manage complex production processes. However, to achieve greater transparency, they needed to optimise work procedures connected with warehouse management. For example, employees involved in the production of automated heat-exchanger manufacturing systems lacked sufficient visibility of current warehouse stock levels. “Our people were often busy searching for the right parts and assemblies in the warehouse, which had a negative impact on process efficiency. For this reason, we wanted to optimise all of our warehouse management and build it upon a stable foundation,” explains Martin Spiegler, head of SAP at ZELTWANGER.

The goal was to have an integrated system that would record all information concerning parts and assemblies for the plant within a production order and bring it together in a unified way. There also had to be a way to e.g. determine which external parts are in stock. It was necessary to start recording incoming goods using a scanner and automatically enter them into the system. Knowledge and clarity regarding inventory levels are a critical factor for starting and completing the production cycle quickly.

Digitalisation of warehouse processes with Aimtec SCIx

It was not, however, possible to map processes properly in the existing SAP system. ZELTWANGER’s management thus decided to find a solution that would make it possible to extend the system accordingly. Martin Spiegler’s team ultimately decided for a technology from a proven IT partner they had worked with for years: “We’ve been cooperating with Aimtec very successfully since 2011, and we have great trust in its deep expertise in SAP optimisation,” confirms Spiegler. The specific solution deployed was Aimtec SCIx. This is an extension to SAP ERP, in the framework of which a warehouse management system (WMS) is running. It provides a realistic digital image of all warehouse and intralogistics processes. Operators use modern scanners from Zebra Technologies running on Android in their day-to-day tasks.

Precision inventory management, plans for further cooperation

The newly created transparency has contributed to better planning and utilisation of warehouse capacity, enabling more efficient use of available space. ZELTWANGER is now saving considerable time and money and can also offer its customers maximum product quality. “Thanks to the greater efficiency of warehouse management we are achieving time savings of up to 60% in the production of thermal management systems. That means that we can produce them twice as quickly with the same resources and deliver machines to customers more quickly. This creates the potential for further capacities and new orders,” notes Spiegler.

“Aimtec provided us with exemplary support throughout the project. Their specialists analysed our warehouse management processes in advance and presented us with expert advice regarding opportunities for optimisation. The deployment of the system was followed by professional training of our users. And even after commissioning, we have continued qualified support from Aimtec – they can flexibly cover all our requirements. We are convinced the Aimtec team’s expert knowledge and commitment will give us valuable support during the planned migration of our SAP environment to the S/4HANA system as well,” Spiegler adds.

“We look forward to continuing our cooperation, and we are already working on projects for the deployment of the WMS in another ZELTWANGER plant, where we will also be optimising the collection of manufacturing data using Aimtec SCIx,” says Aimtec SAP consultant Michal Macht.

ZELTWANGER Group

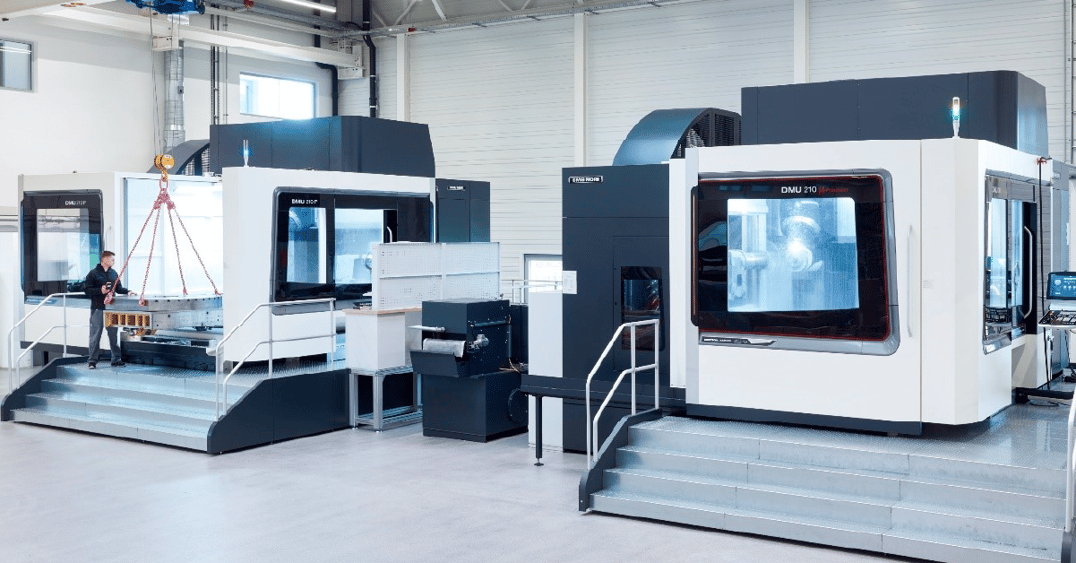

This group focuses on promising areas of business, in which it is among the technology and innovation leaders. Its portfolio includes services connected with the production of high-precision components for mechanical engineering, devices for automated tightness testing and systems for the manufacturing and functional testing of modern thermal exchangers (heat management). The group was founded in 1982, and its headquarters is located in Tübingen, Germany, in the state of Baden-Württemberg. It is organised as a holding company and is made up of eight independent companies, with over 470 employees at six sites in three nations of the world. In 2023 it achieved a turnover of 81 million euros. Two plants are located in the Czech town of Kuřim. The company works with a wide range of industrial sectors. They include the automotive industry and the electromobility segment, battery and semiconductor production, medical technology, the optics industry, packaging manufacturers and the food processing sector.

About Aimtec

For over a quarter-century, we’ve been guiding automotive companies on their way to digital transformation. We help them to digitalise and automate production, logistics and the supply chain into one functioning whole so that their transformation truly benefits them. We empower our customers to learn, standardise and be efficient while also flexibly responding to the changes they face every day.

Media contact:

Petra Troblová

Key Account Marketing Manager

petra.troblova@aimtecglobal.com

+420 724 284 141

Download the Press Release